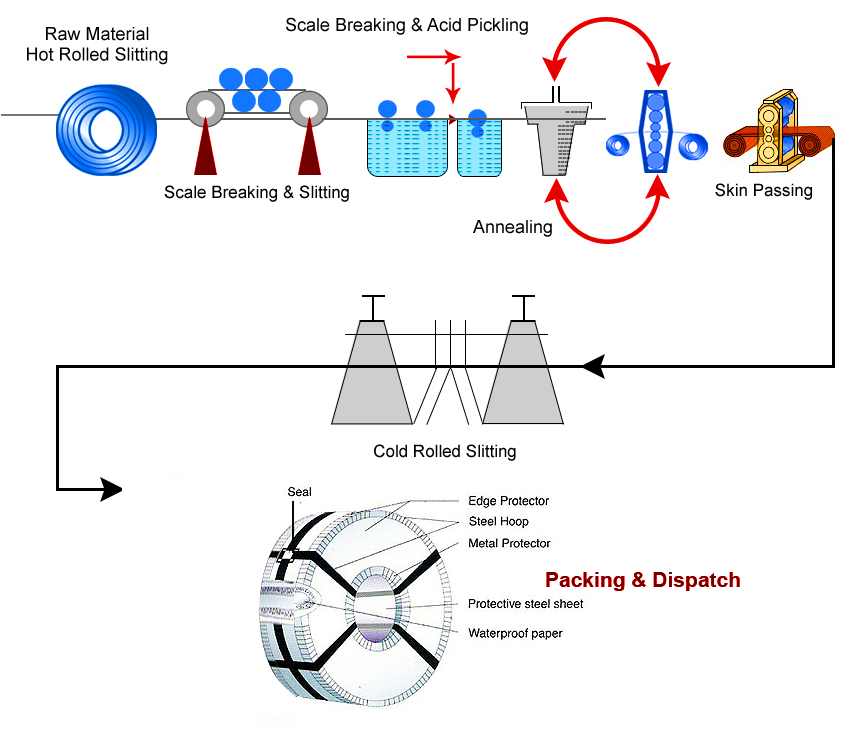

PROCESS FLOW CHART

The basic raw material is medium carbon & high carbon hot rolled coils. The coils are slitted on slitting machine for obtaining the required width of hot rolled strips. After slitting these hot rolled strips are acidly pickled through the continuous pickling line for removal of scale. The Pickled coils are cold rolled on 4 Hi AGC cold rolling mill to obtain the required thickness and annealed in HSD fired bell-type annealing furnace for bright annealing. In case of medium and high carbon coils, the process of rolling and intermediate annealing can be repeated to a number of times depending upon the final thickness to be obtained. These coils after final rolling are slitted on CR slitting machine for obtaining the final required width. If needed the cold rolled coils are cut to desired lengths on a cut to length machine. Finally, the strips are packed for dispatch after oiling.